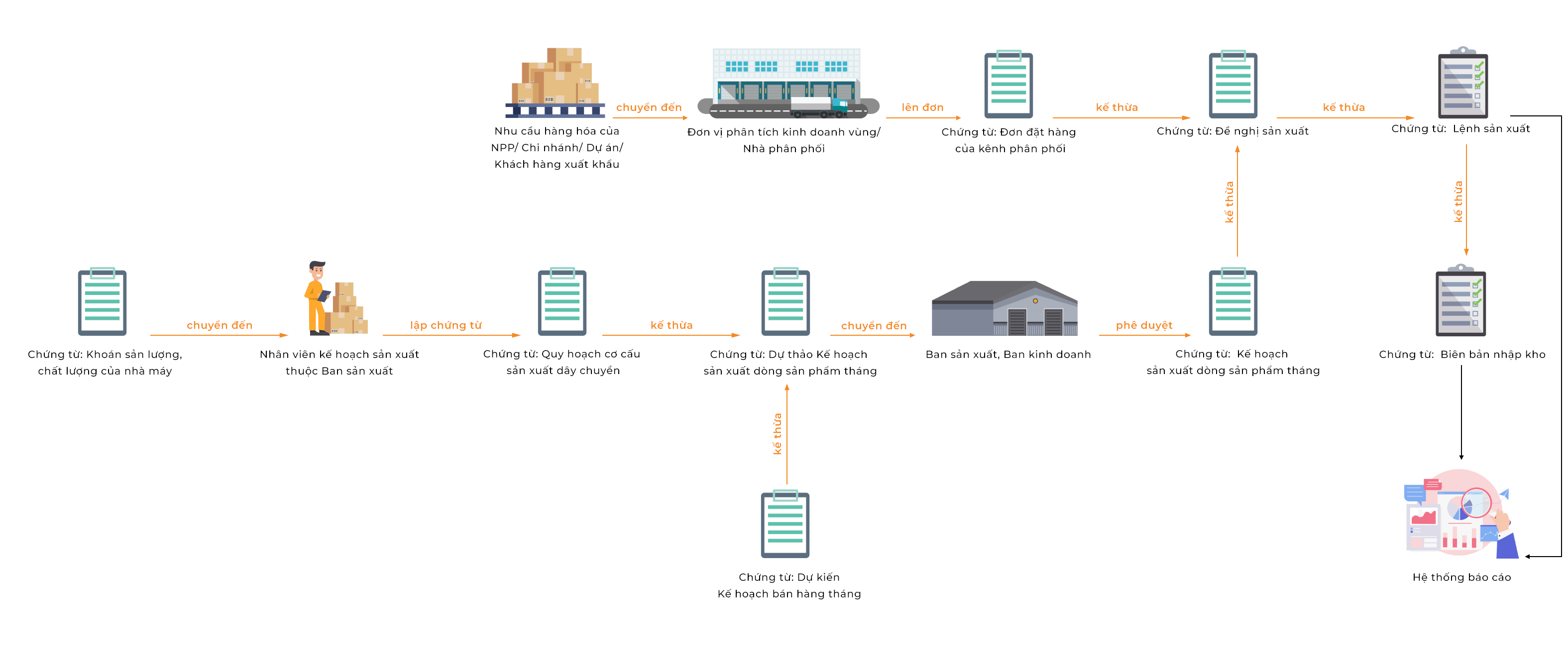

As for manufacturing enterprises, tracking the cycle from sales orders to production, warehousing and goods delivery can be considered as the backbone of the enterprise’s value chain operation. Therefore, inward transformation projects (Operational excellence) often aim to optimize this cycle of the Value Chain. The Production and Sales management application built by SBA simulates the cycle from placing an order, through other steps in the internal value chain of the Enterprise to the delivery of goods to the customer, to ensure that input information is recorded at the place of origin, reuse at the next step of the cycle, record changes as the transaction goes through the cycle until inventory, delivery.

The Group’s production planning and execution is a cycle involving many job positions, documents and inter-departmental data, so if there is no standard and regulation, it will be difficult to control, and there is a lack of information for the operational processes or management decisions. With the increasing scale and number of transactions, the Group faces many problems arising from this core cycle such as:

- Unifying the product code (Smart object), business documents (Documents) and process (Workflow) of the Group’s monthly production and sales management to ensure that data is controlled.

- Numerous job positions, people involved in the process in many departments and business units hinder the exchange of information, missing the timeliness of data.

Difficulties faced by customers

- Difficult to track and synthesize information due to inconsistency in the document form.

- Difficult to track change.

Reasons for choosing Symper

Weaknesses of solutions on the market:

- Most of the solutions on the market partially solve the problem because they are built based on the specific needs of a certain group of businesses.

- Difficult to change. In particular, the Group is in the process of restructuring, so later corrections are certain to happen.

- Applying the business group and solutions available on the market to customize or develop a new one suitable for the enterprise will consume a lot of time and effort to understand the management system.

Symper offers:

- The Standard Business Process Re-engineering methodology developed, tested and applied by Symper in Transformation Projects that Symper has participated in.

- The knowledge and experience of Symper Consultants team has accumulated over many years of participating in business transformation projects to build information systems, standardize and digitalize business processes.

- The SAB tool platform which helps to quickly digitalize business processes and flexibly maintain, update and expand applications according to the changes of the Organization.

- Project management capacity deployed with a large number of customers (01 central production management office, 03 manufacturing plants, 02 sales offices) for this application.

How Symper built the Production and Sales management module

The implementation goes from the stage of survey, analysis and design to decompose the business process into 6 main components that are the input for application digitalization by SAB.

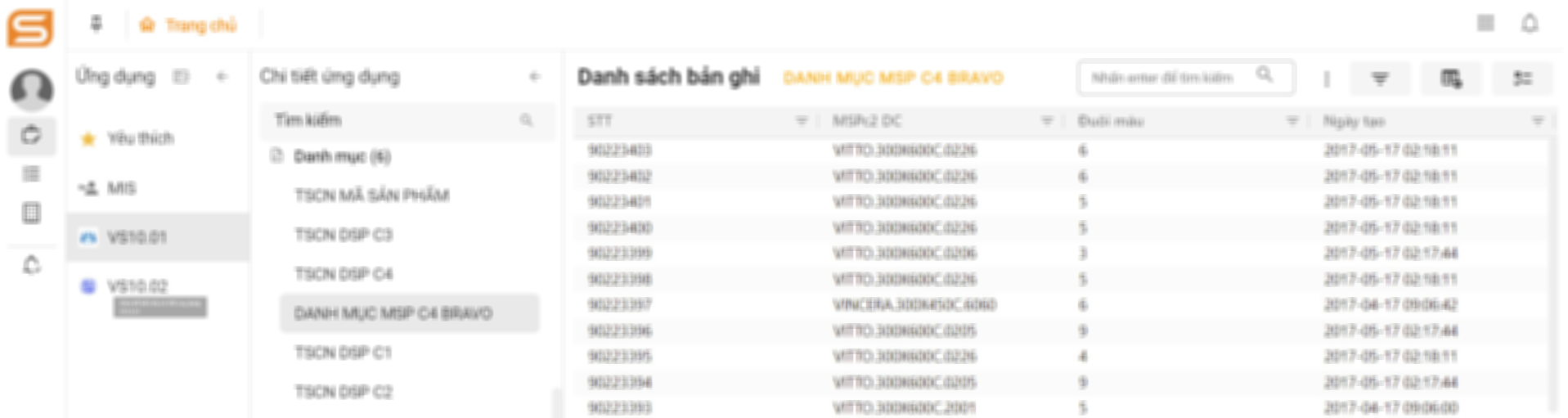

- Synthesize and store data of all kinds of Smart Objects within the application

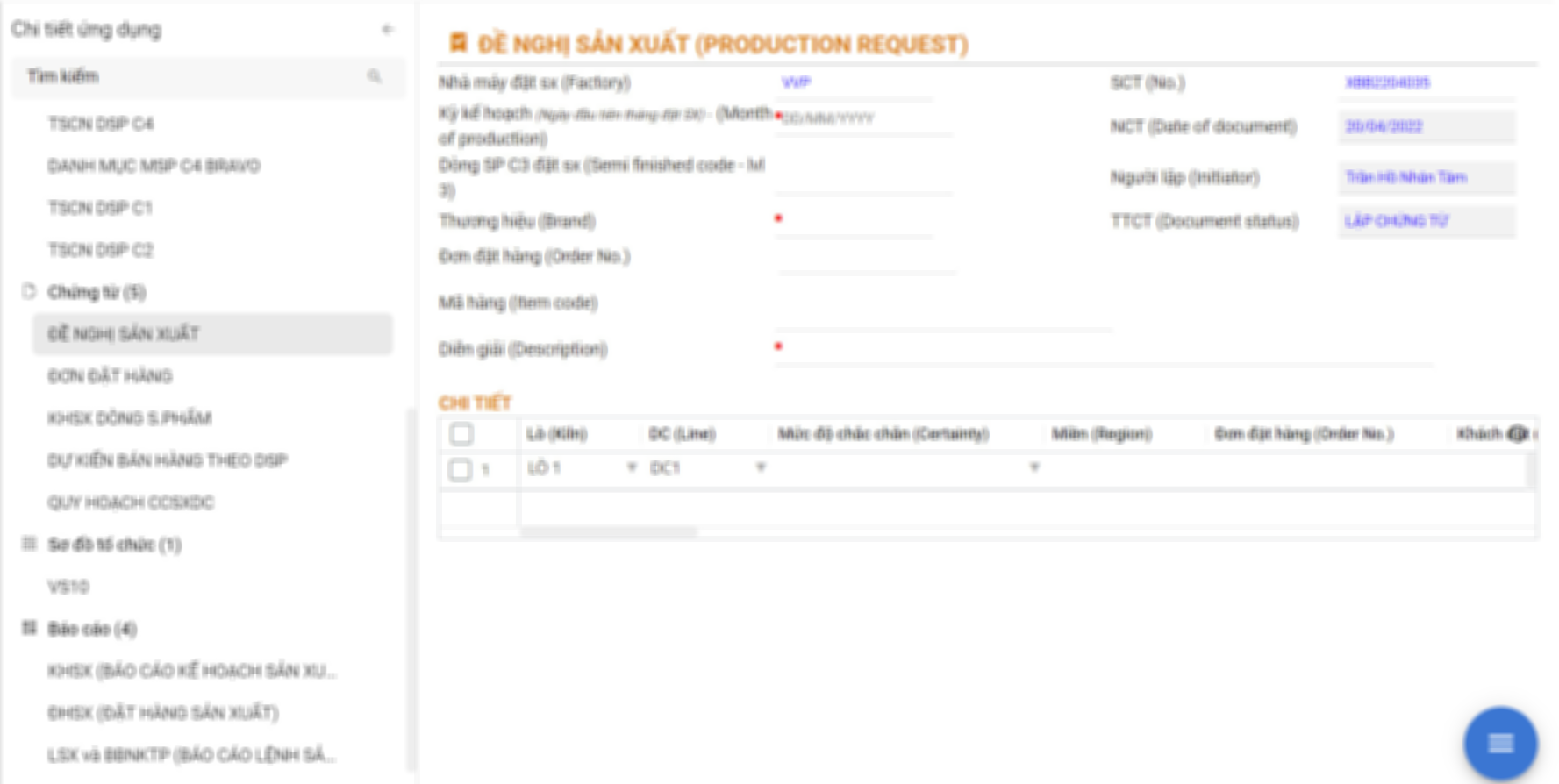

- Documents (Form/Document) are standardized and organized to ensure seamless information, optimize input operations, and avoid errors.

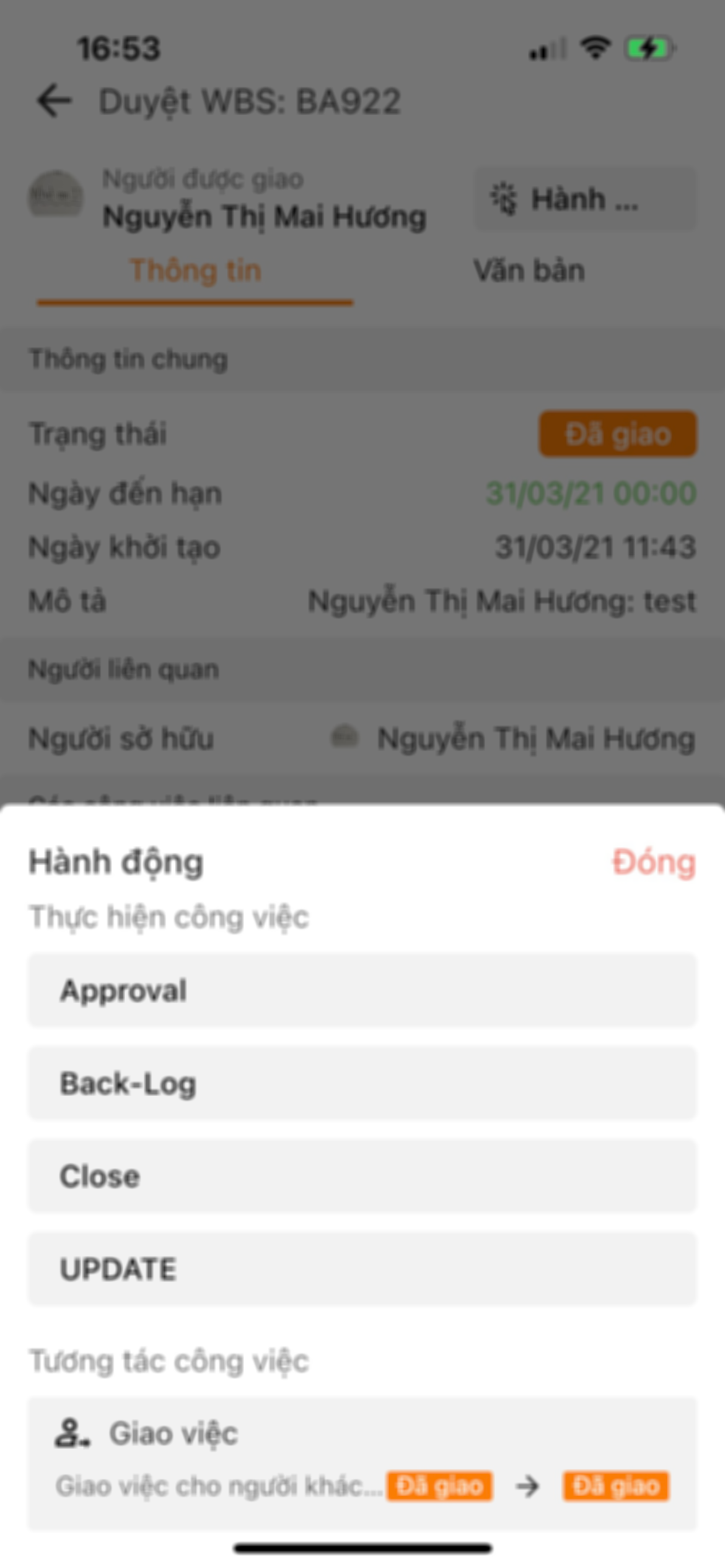

- Assign document creation, approval, or update to standardized Workflows that ensure proper execution and tracking status of the process.

- Tasks within Workflows are circulated among job positions of the Organization Chart.

- Reports synthesizing and processing Data are built from dataflows that track the process from placing order to production and warehousing accurately and in a timely manner.

After 3 months of survey, construction and trial, the results brought to the Tile Group with a turnover of USD 250 million/year are shown in the following aspects:

- Tracking the process of placing order, production and warehousing for each transaction of each customer;

- Data quality increased and data collection time for reporting, analysis and decision making decreased.

- Sales staff can look up, answer customer inquiries, questions and inform the status of each order thanks to linked information, creating a continuous and accessible workflow for trace, analysis and experience gain.

- Managing the uniqueness of the Group’s Product Management codes.